Discover the Importance of Sewer Line Tests for Homeowners

Plumbing pressure testing is the controlled pressurization of water, air, or gas within piping systems to verify pipe integrity, locate leaks, and prevent costly property damage. This article explains plumbing pressure testing and related diagnostics—hydrostatic testing for under-slab lines, sewer line air and water tests, sewer camera inspection, water line pressure checks, and gas line pressure verification—to help homeowners and businesses spot problems early and choose the right test. Many property owners face issues like slab leaks, sewer infiltration, or unexplained pressure loss that lead to foundation damage, mold, and high utility bills; targeted pressure testing provides a reliable solution by isolating sections and confirming failures before invasive repair work begins. You will learn what each major test involves, the tools technicians use, typical signs that trigger testing, safety protocols for gas lines, and the specific benefits of early detection for cost savings and water conservation. The sections below cover definitions and mechanisms first, then step-by-step sewer testing comparisons, water line diagnostics, gas safety protocols, and a benefits summary that ends with clear next steps for scheduling professional inspections in Owasso and Tulsa.

TL;DR

Plumbing pressure testing verifies pipe integrity and locates leaks using controlled pressurization.

It covers various diagnostics: hydrostatic, sewer air/water, camera inspection, water line, and gas line tests.

Essential for homeowners and businesses to detect issues like slab leaks, sewer infiltration, and pressure loss early.

Prevents costly damage (foundation, mold, high utility bills) by isolating problems before invasive repairs.

Offers benefits like cost savings, water conservation, and enhanced property protection.

What Is Plumbing Pressure Testing and Why Is It Essential?

Plumbing pressure testing is the process of applying and holding pressure in a pipe segment to verify its ability to retain fluid or gas, which reveals leaks and compromised pipe integrity. This method works by creating a controlled pressure differential and monitoring for pressure loss or visual/sonic indicators that signal leakage, and it directly reduces the risk of water intrusion, mold growth, and structural damage. Property protection is the primary benefit because testing allows targeted repairs before minor leaks escalate into . Understanding the kinds of pressure tests available — hydrostatic, air, water, and gas line tests — helps owners choose the correct diagnostic path and prioritize prevention measures.

What follows is a practical breakdown of the hydrostatic test steps and the instruments typically used to confirm under-slab leaks, which prepares readers to assess recommendations from a licensed plumber. This leads into a concise, stepwise explanation of the for readers ready to evaluate or request service.

What Does a Hydrostatic Plumbing Test Involve?

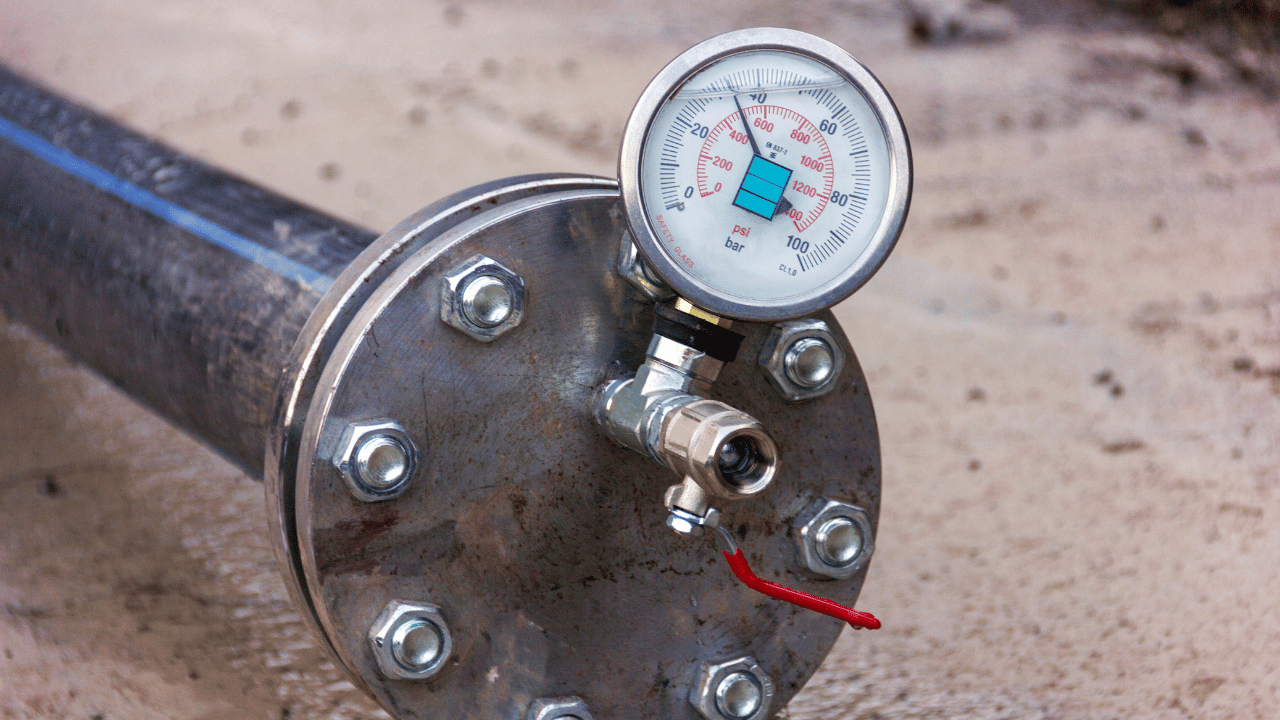

A hydrostatic plumbing test isolates the under-slab drain or supply segment, seals it with an inflatable test ball or plug, and fills the isolated section with water while monitoring pressure and flow. Technicians attach a calibrated pressure gauge and pressurize the line to a set test pressure, then observe for pressure decay or visible leak indicators; a stable pressure indicates the segment is sound while a drop signals a leak requiring pinpointing. Typical instruments include an inflatable test ball, pressure gauge, hose connections, and complementary tools like acoustic listening devices and thermal imaging to localize leaks non-invasively. The outcome either confirms pipe integrity or triggers targeted excavation, camera inspection, or slab access to repair the identified breach.

By outlining the instruments used in this test, homeowners can request specific diagnostics and compare proposals from contractors, which transitions naturally into how those test results translate into tangible property protection.

How Does Plumbing Pressure Testing Protect Your Property?

Plumbing pressure testing protects property by detecting leaks when they are small and repairable, preventing progressive damage such as soil erosion under foundations, interior water damage, and mold colonization. Early identification reduces repair scope from full foundation remediation to focused pipe repair or targeted slab cutting, which lowers overall cost and disruption. Documented test results also provide useful records for insurance claims and home resale disclosures, enhancing property value and buyer confidence. Understanding these protective outcomes helps owners prioritize periodic testing when they notice early warning signs, which we explore in the section next.

How Does Hydrostatic Testing Detect Slab Leaks and Prevent Foundation Damage?

Hydrostatic testing detects slab leaks by isolating under-slab drain or supply lines, filling that isolated section with water, and holding it at pressure to reveal pressure loss or flow that originates beneath the slab. This method directly isolates the suspect line so technicians can confirm whether a leak exists under concrete without unnecessary excavation, which prevents broader foundation damage by enabling timely targeted .

In regions with expansive clay soils, early detection is especially important because soil movement amplifies the risk of structural settlement when moisture migrates under foundations. After explaining the detection mechanics, the following subsection lists signs that should prompt hydrostatic testing.

What Are the Signs You Need Hydrostatic Testing for Slab Leak Detection?

Recognizing warning signs helps homeowners know when to request hydrostatic testing to avoid progressive foundation issues. Common indicators include unexplained high water bills, warm or damp floor spots over a concentrated area, new hairline foundation cracks, and localized floor or slab settling that appears without other causes. Additional signs are recurring lawn saturation or soggy patches near the foundation and the sound of running water when fixtures are off; these symptoms suggest water is escaping beneath the slab and warrant immediate diagnostic testing.

Prompt recognition of these symptoms supports rapid intervention, which leads into an overview of the and complementary methods professionals deploy to increase detection accuracy.

What Tools and Methods Are Used in Hydrostatic Testing?

Hydrostatic testing uses specific instruments to isolate, pressurize, and verify the condition of under-slab lines; combining these tools reduces false positives and speeds leak localization. Key tools include an inflatable test ball to seal pipes, calibrated pressure gauges to monitor hold times, hoses and adapters to introduce test water, and acoustic listening devices that detect escaping water sounds through concrete. Complementary diagnostics such as thermal imaging cameras and moisture meters identify temperature differentials and damp zones associated with leaks, while sewer cameras can confirm internal pipe damage. Combining hydrostatic isolation with acoustic and thermal methods improves accuracy and minimizes invasive excavation.

This shows that hydrostatic testing is a multi-tool process where isolation plus detection methods deliver reliable leak confirmation and guide the least-invasive repair plan. Next, we explain how combining these shortens repair time and lowers costs by allowing targeted excavation.

Half Moon Plumbing brings local hydrostatic testing experience to Owasso and Tulsa property owners, combining isolation procedures with acoustic and thermal diagnostics to pinpoint under-slab leaks efficiently. As a trusted local provider operating in Owasso, Tulsa, and surrounding areas, Half Moon Plumbing focuses on clear explanations and evidence-based recommendations for repair options, and adheres to a transparent, up-front pricing approach that helps homeowners evaluate repairs. The page's primary intent is to attract new customers for plumbing services by providing clear information, demonstrating expertise, and encouraging service requests; readers who prefer local support can rely on licensed, highly trained to carry out these technical diagnostics while documenting findings for insurance or real estate needs.

What Are Sewer Line Pressure Testing and Leak Detection Services?

Sewer line pressure testing and leak detection services assess the integrity of sewer drains using pressurization, camera inspection, and targeted diagnostics to identify infiltration, blockages, and defects. These services differ by test type—air tests, water tests, and CCTV camera inspections—each suited to different conditions such as access, depth, and suspected failure mode, and they aim to detect problems like tree root intrusion, pipe bellies, and corroded joints. The section that follows compares air and water tests so property owners understand which approach fits their situation.

How Do Air and Water Tests Identify Sewer Line Leaks?

Air and water sewer tests follow different mechanics but both detect leak presence by monitoring pressure behavior in a sealed segment; the choice depends on site constraints and safety. An air test pressurizes the isolated sewer section with compressed air and measures decay; it is fast and useful where lines can be sealed, but must be performed carefully to avoid over-pressurization. A water test fills the segment and monitors level or pressure loss; it is often preferred for low-lift gravity sewers and where air tests present safety concerns. Each test has trade-offs: air tests are quicker and can be performed with minimal water, while water tests better simulate actual hydraulic conditions and avoid air-related safety issues in deep or fragile lines.

These procedural contrasts lead naturally to when to use a to confirm cause and plan repairs, which the next subsection examines.

This clarifies that test selection is driven by pipe access, depth, and the need for visual confirmation; using a sewer camera often follows a pressure test to find the exact defect. Next, we detail how camera inspection enhances leak detection and reduces unnecessary excavation.

Research indicates that all leak test methods for real-scale sewage pipes can detect leaks with a very high degree of reliability.

Evaluating Sewage Pipe Leak Test Methods for Reliability

Tests to determine the tightness of wastewater pipes can in some cases produce results that are worthy of discussion. Therefore, testing procedures for real-scale sewage pipes used for house connections were evaluated and data were statistically analysed. The results of the investigation showed that leaky pipes are detected with a very high degree of reliability by all leak test methods.

Evaluation of testing procedures for real-scale sewage pipes, S Ulutaş, 2021

How Does Sewer Camera Inspection Enhance Leak Detection?

Sewer camera inspection uses a flexible, high-resolution CCTV probe to visually inspect the interior of sewer lines, revealing defects such as root intrusion, cracks, misaligned joints, and pipe bellies that pressure tests only indicate indirectly. Camera footage enables technicians to determine defect type, approximate location and extent, and whether spot repair, re-lining, or replacement is required, which minimizes guesswork and limits excavation to targeted locations. The method is non-invasive, documents the problem for records, and pairs effectively with pressure testing: tests identify a problem and the camera confirms cause and repair strategy. This combined approach accelerates decision-making and reduces total repair cost and timeline when planning work.

Transitioning from sewer diagnostics, the next section focuses on water line pressure testing for supply lines and how technicians diagnose high or low pressure issues.

How Is Water Line Pressure Testing Performed to Identify Leaks and Pressure Issues?

Water line pressure testing isolates supply segments and measures static and dynamic pressure to detect leaks, faulty pressure-reducing valves, or main line deterioration that causes high or low pressure at fixtures. The process typically involves shutting off branches, attaching a pressure gauge to the main, monitoring holding pressure, and performing isolation tests to determine whether the problem originates inside the structure or on the service line. Accurate pressure measurement identifies whether a pressure regulator adjustment, targeted leak repair, or main replacement is necessary, which streamlines corrective action and avoids unnecessary interior disruption.

The following subsection lists common signs owners should watch for to trigger water line testing.

What Are Common Signs of Water Line Leaks and Pressure Problems?

Homeowners can spot water line issues through a combination of visual and behavioral signs that indicate leaks or pressure irregularities requiring professional testing. Key symptoms include low pressure across multiple fixtures, continuous movement of the water meter when all fixtures are closed, wet or sinking patches in the yard, and unexpectedly high water bills without a change in usage. Additional indicators are sudden appearance of discolored water, gurgling sounds in drains, or pressure spikes at single fixtures that suggest internal valve failure or a failing pressure regulator. Recognizing these signs early allows timely pressure testing and targeted repairs to prevent larger failures.

These observable symptoms guide plumbers to the appropriate , which we outline next as a systematic approach to isolating high versus low pressure sources.

How Do Plumbers Diagnose High and Low Water Pressure?

Plumbers diagnose pressure problems using pressure gauges, isolation steps, and flow testing to determine whether issues are internal or external to the building, and to identify corrective measures. The typical process starts by attaching a pressure gauge at the service line or PRV location to measure static pressure, then isolating internal plumbing by shutting off the main to see if pressure holds or drops, which differentiates between internal leaks and service line failures. Troubleshooting continues with fixture-by-fixture isolation, PRV inspection or adjustment, and, if needed, excavation for service-line inspection or replacement. Accurate diagnosis leads to targeted remedies such as PRV replacement, localized pipe repair, or main line replacement based on the measured data.

After water line protocols, are discussed to ensure readers understand legal and emergency considerations.

Why Is Gas Line Pressure Testing Critical for Safety and Leak Prevention?

Gas line pressure testing is a safety-critical verification performed after new installations, alterations, or repairs to ensure lines hold the required test pressure and present no dangerous leaks that could lead to fire or explosion. Because gas leaks pose immediate hazards, testing confirms integrity by isolating the segment, applying regulated test pressure (often with inert test media per code), and monitoring for pressure decay; only licensed technicians following code-compliant procedures should perform these operations. Gas line testing prevents accumulation of combustible gas in occupied spaces, reduces the risk of ignition events, and ensures compliance with local safety requirements.

The next subsection outlines the used by qualified professionals.

How Is Gas Line Pressure Testing Conducted?

A standard gas line pressure test involves isolating the test section, applying a measured test pressure using calibrated gauges and pumps, and holding that pressure for a prescribed duration while monitoring for decay or audible leaks. Technicians use inert test media and adhere to maximum test pressures defined by code, then perform soap or electronic leak detection on fittings and joints to confirm integrity; if pressure drops, the line is depressurized and repaired before retesting. Equipment typically includes calibrated gauges, hand pumps or compressors with regulators, and electronic leak detectors that sense combustible gases at fittings. Successful tests conclude with documented readings and ready-to-use service lines after purge and relight procedures where applicable.

Following the test procedure, strict safety protocols must be observed to protect occupants and technicians, which the next subsection lists.

What Safety Protocols Are Followed During Gas Line Testing?

Gas line testing requires rigorous safety protocols including pre-test notifications, area ventilation, lockout/tagout procedures, and the presence of licensed technicians to manage hazards and emergency response. Technicians verify appliance isolation, post warning signage, use appropriate personal protective equipment, and ensure ignition sources are controlled or removed during testing to prevent accidental ignition. Electronic combustible gas detectors and soap testing complement pressure monitoring to identify leaks quickly; if a leak is detected, procedures call for immediate evacuation, ventilation, and notification of the appropriate emergency services or utility authorities. These protocols protect occupants and ensure testing meets regulatory safety standards.

With safety procedures explained, the article next summarizes the tangible benefits of pressure testing and how early intervention saves money and protects property.

What Are the Key Benefits of Plumbing Pressure Testing for Homeowners and Businesses?

Plumbing pressure testing delivers clear benefits: early leak detection lowers repair costs, prevents structural and environmental damage, conserves water, and documents system condition for insurance or real estate purposes. By confirming pipe integrity before visible deterioration occurs, testing helps avoid full-scale replacements and reduces downtime for businesses that depend on reliable plumbing.

Pressure testing also supports water conservation by identifying and repairing hidden losses that waste resources and elevate utility bills.

The following subsection quantifies cost-saving pathways and practical examples to illustrate the of early detection.

How Does Early Leak Detection Save Costs and Protect Property?

Early leak detection reduces repair scope and associated costs by converting large, disruptive projects into targeted interventions such as spot repairs, pipe relining, or localized slab access, thereby preserving finishes and landscaping. For example, a localized under-slab repair guided by hydrostatic testing and acoustic localization typically costs significantly less than full slab removal and foundation remediation; documented test results also strengthen insurance claims and minimize dispute over damage timing. Preventing water intrusion averts mold remediation costs and structural degradation, and the cumulative savings for homeowners and businesses often justify periodic pressure testing when symptoms appear.

These financial and structural advantages motivate proactive testing rather than reactive emergency .

This comparison highlights how selecting the right test protects assets and reduces downstream costs; knowing these outcomes helps owners prioritize which diagnostics to request.

How Does Pressure Testing Contribute to Water Conservation and Peace of Mind?

Pressure testing contributes to measurable water conservation by identifying hidden leaks that, when repaired, eliminate continuous water loss and lower utility consumption; even small leaks can waste thousands of gallons per year, so detection yields both environmental and financial gains. Beyond measurable savings, documented testing provides peace of mind through formal verification of system integrity, useful for business continuity planning and real estate transactions where documented plumbing condition matters. For property owners who want professional support, Half Moon Plumbing offers local service options in Owasso, Tulsa, and surrounding areas with transparent up-front pricing and a satisfaction guarantee. To request inspection or technical testing, homeowners and businesses can contact Half Moon Plumbing by phone to schedule an evaluation with licensed, highly trained plumbers who document findings and recommend precise repairs.

This practical benefit orientation completes the technical and procedural coverage of pressure testing and directs readers toward professional next steps to protect property and conserve water.

Detect Leaks Head On

Plumbing pressure testing is essential for early leak detection, which not only saves homeowners and businesses from costly repairs but also conserves water and protects property integrity. By understanding the various testing methods and their benefits, property owners can make informed decisions that enhance their plumbing systems' reliability. For those seeking professional assistance, Half Moon Plumbing offers expert services in Owasso and Tulsa, ensuring thorough inspections and precise repairs. to schedule your plumbing pressure testing and safeguard your property.